Bioheat® fuel

Technical Guidance

Demonstration

B-5 – B100 / Beckett AFG

Demonstration

B-5 – B100 / Carlin EZ1

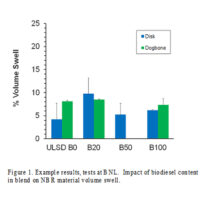

A significant amount of new testing data on nitrile performance in U.S. heating oil equipment with biodiesel meeting today’s stringent ASTM standards is now available. This recent testing shows common nitrile elastomers in typical heating oil burner pumps in the U.S. perform the same or better using B20 than those using conventional No. 2 heating oil. The validity of this testing is supported by elastomer manufacturers marketing B-100 nitrile which could, if appropriate, be used by burner manufacturers.

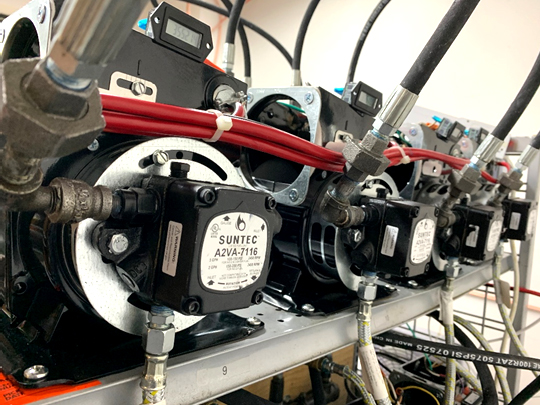

In a NORA-sponsored study, UL conducted testing and evaluation of seal materials used in legacy pumps against these new materials test requirements. The tested legacy seal materials passed the current standard indicating that it would be acceptable to use the older version pumps rated only for B0 up to the B20 levels.

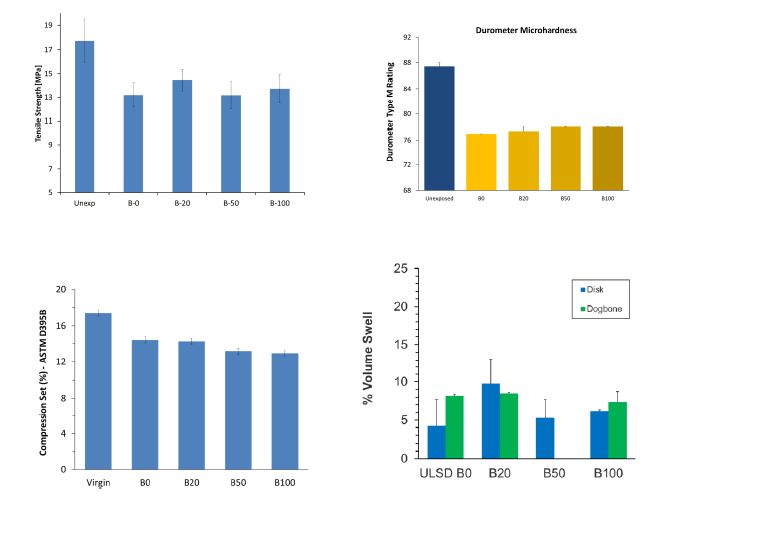

This study investigated the effects prolonged exposure to biodiesel may have on the pump piston and other parts of the pump by cycling them up to 500,000 cycles with various blends of biodiesel up to B100. The number of cycles simulates ~50 years of field operation given an estimated ~10,000 cycles annually. The same tests were also performed on pumps with No. 2 heating oil (which can contain up to 5% biodiesel in the Downstate New York area; hence it will be called B5) as a control. There were also scheduled break points to examine the condition of the pumps visually and determine cutoff performance.

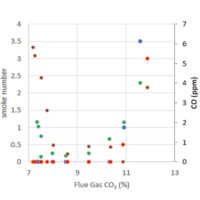

These reports were excerpted from B20 to B100 Blends as Heating Fuels by Dr. Thomas A. Butcher & Rebecca Trojanowski from the Sustainable Energy Technologies Department/ Energy Conversion Group, Brookhaven National Laboratory

These technical summaries were excerpted from B20 to B100 Blends as Heating Fuels Appendix 1 by Dr. Thomas A. Butcher & Rebecca Trojanowski from the Sustainable Energy Technologies Department/ Energy Conversion Group, Brookhaven National Laboratory for submission to ASTM in support of evaluation of changes to the ASTM D396 standard.