Michael Devine, President, NORA

A unique opportunity this spring

As I sit down to write this article, Major League Baseball Spring training has just started, and the liquid heating industry is relishing one of its coldest heating seasons in quite some time. While September through November were warm and felt as if Mother Nature was pushing the Summer and Fall seasons out as long as possible, December finally arrived and with it began a “normal” winter heating season. For the first time in many years, liquid heating marketers went into a six to seven-day delivery work week. Service technicians were working consecutive evenings, and the phone was consistently ringing in the offices with worried souls fearful of running out of oil due to the cold Winter evenings ahead.

As we run through the finish line of this heating season, you may have for the first time in a while added capital to deploy. Now, if it was me back in the day, I certainly would be considering a new delivery vehicle and/or service van, but what other items should you consider? How about your customers, what does this “normal” heating season mean to them? While this has been a well-needed Winter for your organization, your customer is coming off a heating season where they spent more money to keep their family warm than they have in many years. They are likely feeling the financial pain associated with the “normal Winter”.

This Spring, you have a unique opportunity: the chance to provide your customers with important information on the value and cost savings of a new and more efficient heating system. Many of today’s new boilers and furnaces are achieving Annual Fuel Utilization Efficiency (AFUE) ratings from the high 80s into the low and mid-90s. The question we are often asked is, “I know we should promote higher efficiency equipment, but how would we go about it?”

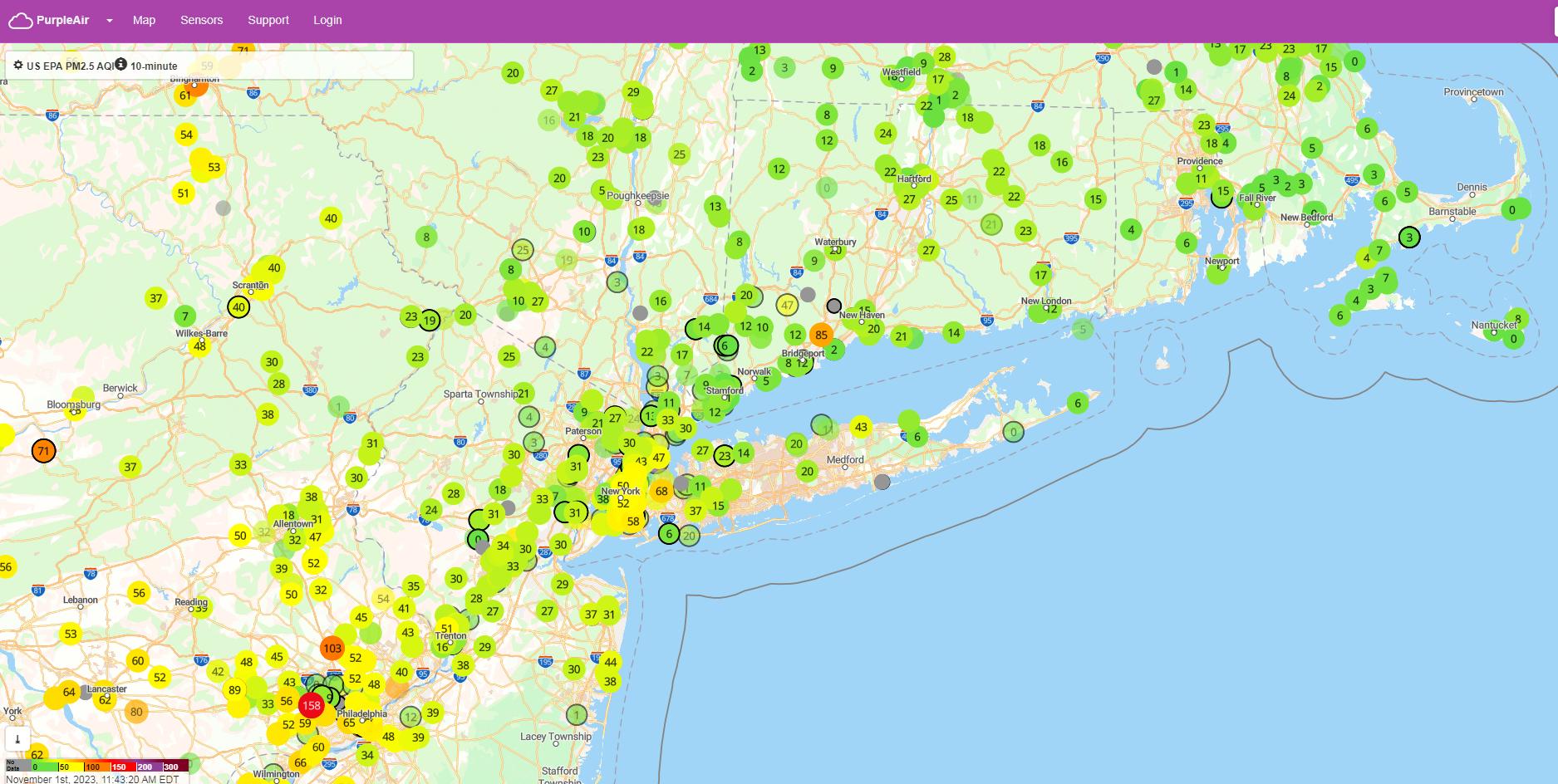

Energy efficiency is at the core of all heating and cooling marketing efforts offered to the U.S. consumer and liquid fuel heating has a great story to tell. Liquid heating fuel marketers can offer a high-value solution to customers. For those who may not remember, NORA completed an extensive report in December of 2021 entitled “Report on Equipment Upgrade and Incentive Project,” which can be found on the NORA website at https://shorturl.at/09QF2.

The report noted that NORA has in place a Consumer Equipment Rebate Program that aims to increase consumer heating system efficiency and safety by encouraging the replacement of existing equipment with new, efficient systems. This report describes the results of analyzing energy savings associated with upgrading 6,412 home heating boiler systems under this program. Savings are estimated based on two methods; the first is an analysis of fuel delivery and degree day data before and after the equipment change-out. The second involves characterization of the type of equipment before and after the upgrade. Both methods gave similar results.

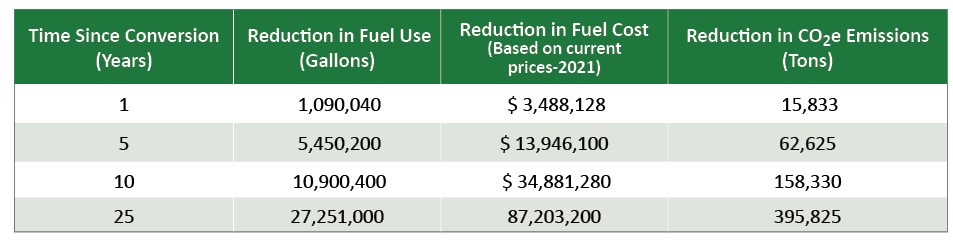

The average fuel savings was found to be 20%. For the 6,412 boiler upgrades done as of the beginning of 2021, the total savings after one year was 1,090,040 gallons, $3,488,128 and 15,833 tons of greenhouse gas (GHG) emissions. These savings were extended to 5, 10 and 25 years (see table below).

Due to the interest and success of the 2021 study, NORA wanted to compile additional updated data. We expanded on the 2021 study and in December 2024, published a follow-up you can find at https://shorturl.at/QRbzw.

In the 2024 updated study, NORA reported that it had extended the analysis of the impact of the NORA Rebate Program from January 2022 to June 2024 using the same methodology. This new report provides an update on the total impact of the NORA Rebate Program from the start of 2021 through June 2024. In the analysis of the more recent rebate data, an additional 3,388 boiler and 973 furnace upgrades were included. This means the Rebate Program has upgraded a total of 9,888 boiler replacements and 3,074 furnaces.

In estimating the total impact of the NORA Rebate Program to date, we took a typical baseline home annual oil consumption of 850 gallons. A 10% average savings for furnaces was assumed. For the set of boilers studied in the 2021 report, a 20% average fuel savings was found. For the set included in the 2022–2024 data, which had a different boiler population set, the average savings was found to be 14%. In addition to the reduced fuel savings associated with the NORA Rebate Program, the reduction in GHG emissions can be estimated using a heating oil emission factor of 209 lbs. CO2e/MMBtu and a fuel heating value of 139,000 Btu/gal.

Based on the two studies, an average of 17% improved efficiency and savings were recognized within both boiler sets. Using an average of 850 gallons purchased by the consumer per year, this equates to approximately 144.50 gallons saved annually. With a baseline cost of $3.61 per gallon, the yearly savings would be $521.45—which is quite impressive.

Couple these savings with a consumer $600-dollar IRS tax credit provided by the Inflation Reduction Act of 2022 and a NORA $500 (average) Consumer Equipment Rebate for new equipment, the year-one savings on a new heating system would come in around $1,621.45—a very good return on investment for the consumer.

Please keep in mind that the higher the efficiency of the system, the greater the savings to the consumer. Therefore, the highest value for the consumer might be in the higher efficiency equipment, not the purchase price of the heating system.

Put the nature of this heating season to good use and offer financial solutions for the higher heating bills your customers endured and help them realize actual savings now, and into the future, through the installation of high-efficiency liquid heating equipment. Your professional recommendations might secure this customer and property for another 25 years of service to your organization—and that’s a winning return on investment in any league.